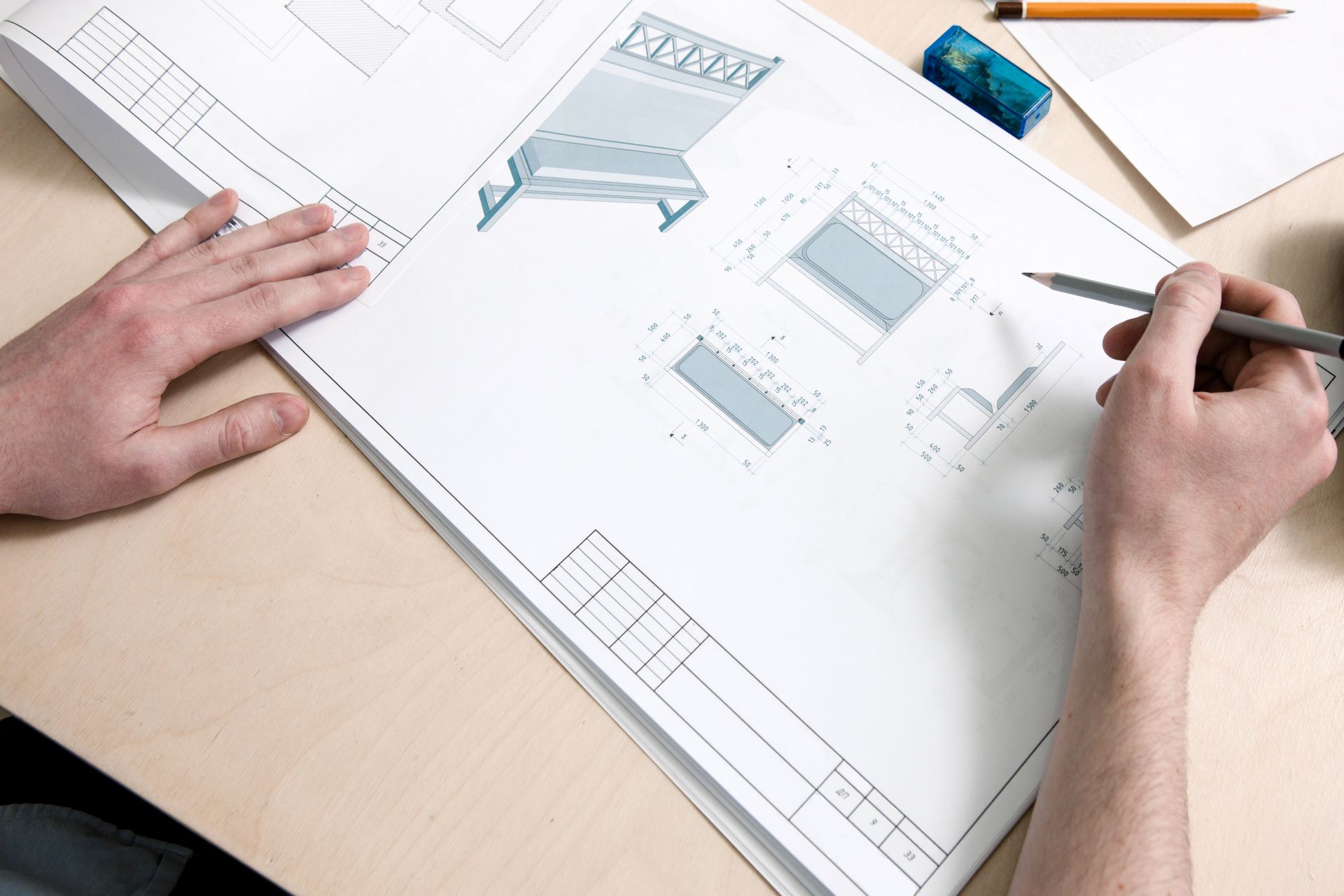

Our BlueCity Designs is blessed to have a highly qualified and skilled R&D team who is widely linked to innovation having vast knowledge about furniture designs and techniques.

With the purpose of developing a new themed product derived from client’s inspiration our team collaborates with them and acquire every needed information for making the specified merchandise. Once a design is finalized it has to go through different segments to check its durability, functionality and force.

This strong wall of our organization influences present and future products by determining and evaluating current and future market trends, keeping us on top its competition.

Designers all around the world works with us creating concepts and designs that balance innovative designs, functional requirements and aesthetic appeal.

The process of furniture design demands creativity, business awareness and skills in marketing, finance, sales and manufacturing. To fulfil this need and enhance our team’s thought process we conduct workshops, seminars and trainings.

To give our buyers their desired output we discuss designs with the client himself for custom ordering and look for ways to improve furniture items that has already been manufactured.

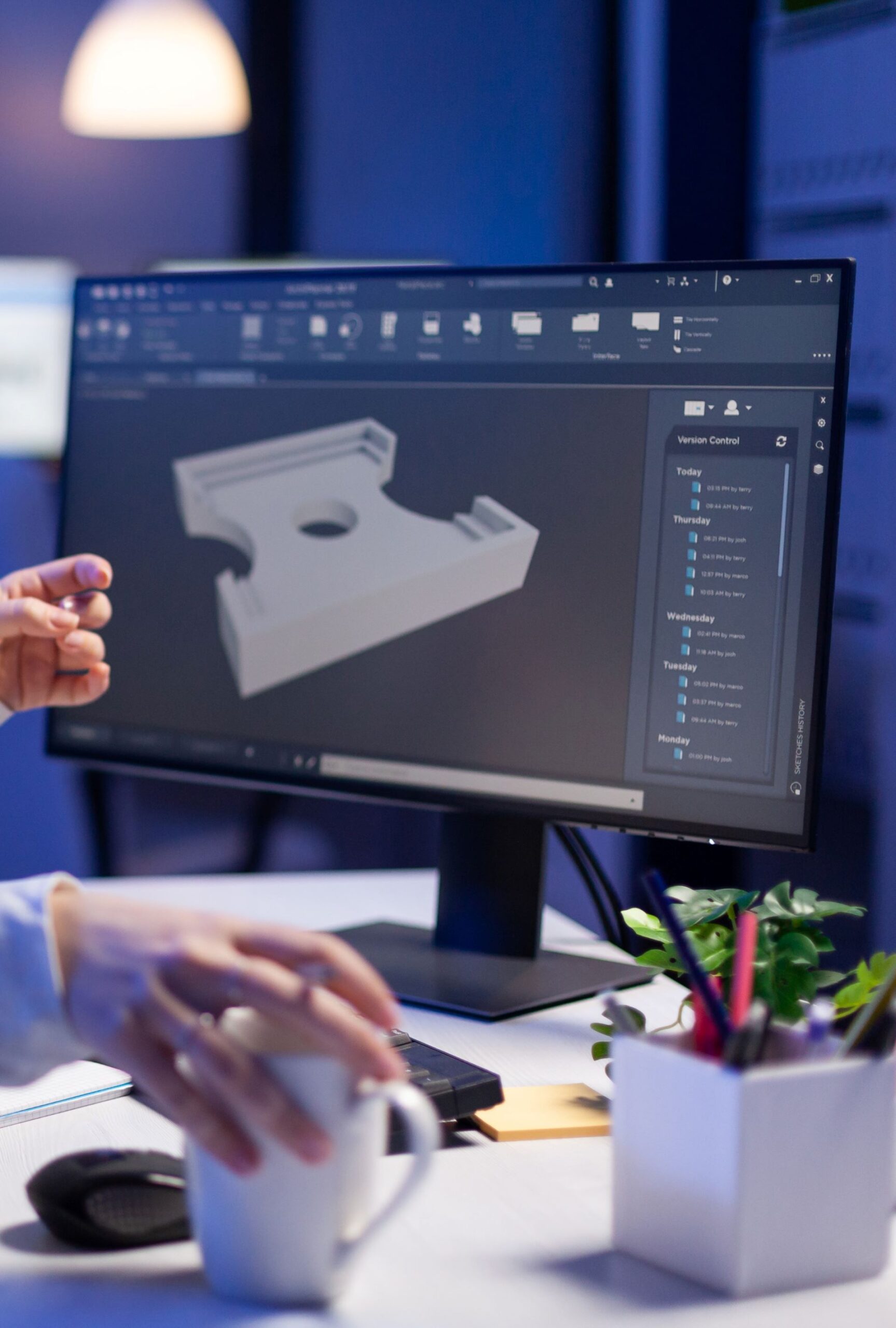

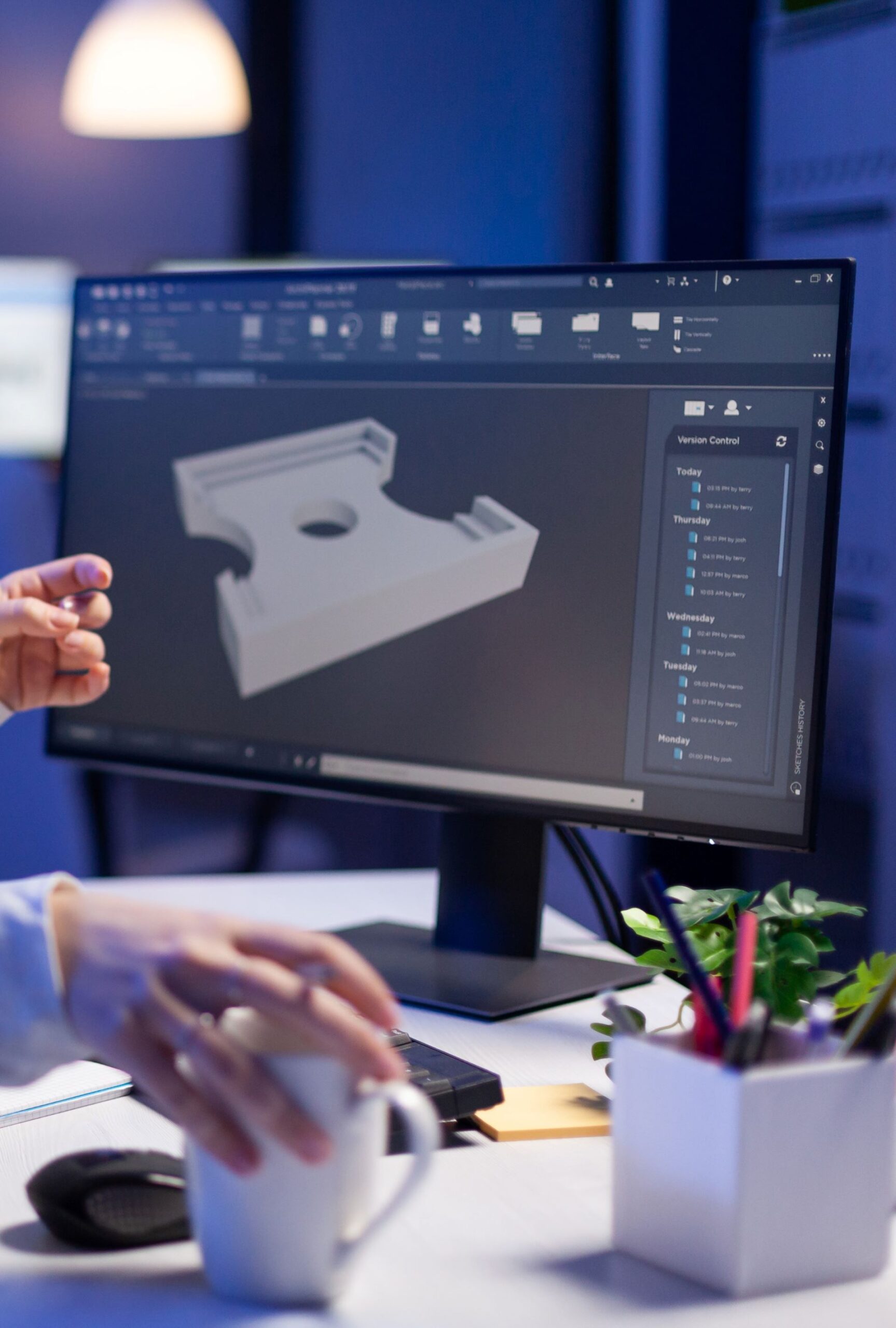

The most unique quality that our craftsperson preserve is that they blend their traditional skills with modern technologies to carve out the masterpiece.

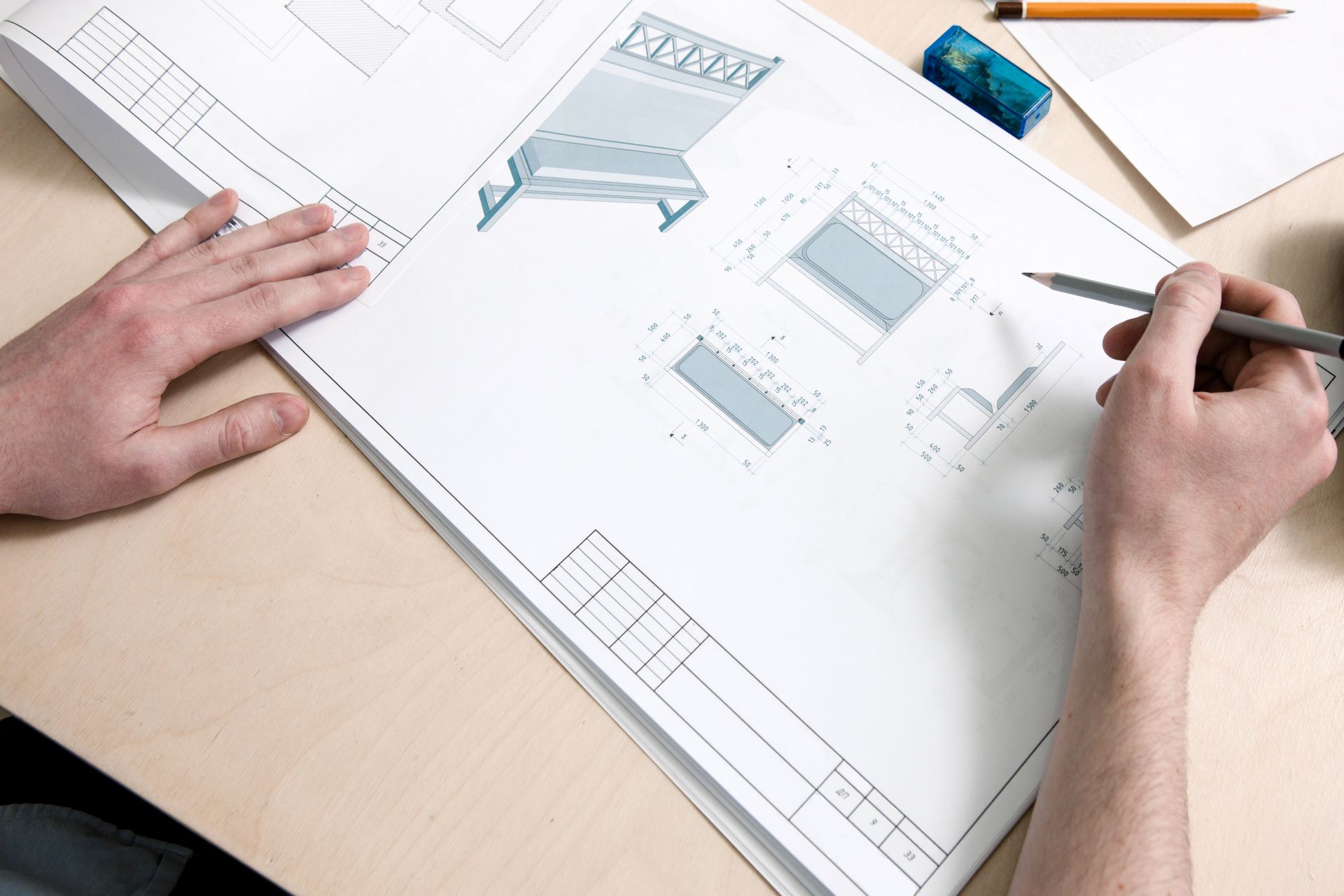

Our BlueCity Designs is blessed to have a highly qualified and skilled R&D team who is widely linked to innovation having vast knowledge about furniture designs and techniques.

With the purpose of developing a new themed product derived from client’s inspiration our team collaborates with them and acquire every needed information for making the specified merchandise. Once a design is finalized it has to go through different segments to check its durability, functionality and force.

This strong wall of our organization influences present and future products by determining and evaluating current and future market trends, keeping us on top its competition.

Designers all around the world works with us creating concepts and designs that balance innovative designs, functional requirements and aesthetic appeal.

The process of furniture design demands creativity, business awareness and skills in marketing, finance, sales and manufacturing. To fulfil this need and enhance our team’s thought process we conduct workshops, seminars and trainings.

To give our buyers their desired output we discuss designs with the client himself for custom ordering and look for ways to improve furniture items that has already been manufactured.

The most unique quality that our craftsperson preserve is that they blend their traditional skills with modern technologies to carve out the masterpiece.

Our Production Process: BlueCity designs goes through a complex and standard set of process, including a number of steps to convert your desired image of home assortment into an output.

An essential first step is to identify both the existing and planned facilities that compete for the right wood raw materials available in an identified procurement zone for which our firm is at the advantage since it has its own plant. This fills us with abundance raw material, picking out the best from the best qualities of varied kind of woods such as Mango, Sheesham wood, Acacia, Old Teak wood and imported wood from different countries.

Chemical treatment is primarily meant to provide a shell to procured raw wood against harmful exterior factors or organisms such as termites, fungi, powderpost beetles to increases the life and structural strength of wood greatly. Thus, to impart resistance to degradation and deterioration of the woodworking we use the finest quality of wood preservatives.

To prevent damage or breakage to the wood we make sure that it goes through a process where it could get rid of the moisture content in walls of wood cells. This process of seasoning minimises structural problems and unequal shrinkage in the wood and ultimately resulting as a material that would stay with you for a longer span.

To get the job done at right time, with the right quantity and quality we make sure to always have myriad seasoned stock which can be allotted as per the need and requirement. The primary aim of being filled with the stock is to never make our buyers wait for what they have been hankering. Thus, with a zone full of seasoned stock we save our party’s time.

Our Production Process: BlueCity designs goes through a complex and standard set of process, including a number of steps to convert your desired image of home assortment into an output.

An essential first step is to identify both the existing and planned facilities that compete for the right wood raw materials available in an identified procurement zone for which our firm is at the advantage since it has its own plant. This fills us with abundance raw material, picking out the best from the best qualities of varied kind of woods such as Mango, Sheesham wood, Acacia, Old Teak wood and imported wood from different countries.

Chemical treatment is primarily meant to provide a shell to procured raw wood against harmful exterior factors or organisms such as termites, fungi, powderpost beetles to increases the life and structural strength of wood greatly. Thus, to impart resistance to degradation and deterioration of the woodworking we use the finest quality of wood preservatives.

To prevent damage or breakage to the wood we make sure that it goes through a process where it could get rid of the moisture content in walls of wood cells. This process of seasoning minimises structural problems and unequal shrinkage in the wood and ultimately resulting as a material that would stay with you for a longer span.

To get the job done at right time, with the right quantity and quality we make sure to always have myriad seasoned stock which can be allotted as per the need and requirement. The primary aim of being filled with the stock is to never make our buyers wait for what they have been hankering. Thus, with a zone full of seasoned stock we save our party’s time.

To provide you the best output for your home assortment, raw wood material goes through a queue of process. We are counted amongst the leading manufacturers and suppliers of furniture for having imported plant setup consisting the right tools and equipment which transforms a plane raw wooden plank into a polished and sturdy woodworking.

The machine process begins with installing the plank into Double side planer. This is woodworking machine of high efficiency is used to trim boards to a consistent thickness throughout their length and flat on both sides. A double side planer helps in achieving uniformly thick boards, eliminating leftover bark or rough spots so, that they can offer seamless performance and results.

When the shards or roughness has been eliminated, Rip saw comes into the process to upgrade its size and texture even more. Rip cut is a cut along the longest dimension of the board or sheet. The intention of this machine is to give out the finest, precise of the cutting. It is also Lens Cutter. It is specially artificed in a way to make cuts in rips pattern which helps for sorting the planks into width wise to create uniformity.

After the material has gone through the ripping procedure, the planks are sized according to the required panel to be made. It is a manual process. Further, each plank is checked and segregated according to their moisture level with help of moisture meter. The moisture is evicted out with the help of this third step in the process.

The next step in the process would be fixing up all the dispersed pieces together. For the purpose to be delivered the plant is installed with Clamping carrier. A clamp is designed to fasten the planks tightly together with the help of adhesive. In this process the wooden planks are kept in the machine glued together and with help hydraulics or pneumatic system pressure is created to join the planks. The machine is geared towards improved production.

To provide you the best output for your home assortment, raw wood material goes through a queue of process. We are counted amongst the leading manufacturers and suppliers of furniture for having imported plant setup consisting the right tools and equipment which transforms a plane raw wooden plank into a polished and sturdy woodworking.

The machine process begins with installing the plank into Double side planer. This is woodworking machine of high efficiency is used to trim boards to a consistent thickness throughout their length and flat on both sides. A double side planer helps in achieving uniformly thick boards, eliminating leftover bark or rough spots so, that they can offer seamless performance and results.

When the shards or roughness has been eliminated, Rip saw comes into the process to upgrade its size and texture even more. Rip cut is a cut along the longest dimension of the board or sheet. The intention of this machine is to give out the finest, precise of the cutting. It is also Lens Cutter. It is specially artificed in a way to make cuts in rips pattern which helps for sorting the planks into width wise to create uniformity.

After the material has gone through the ripping procedure, the planks are sized according to the required panel to be made. It is a manual process. Further, each plank is checked and segregated according to their moisture level with help of moisture meter. The moisture is evicted out with the help of this third step in the process.

The next step in the process would be fixing up all the dispersed pieces together. For the purpose to be delivered the plant is installed with Clamping carrier. A clamp is designed to fasten the planks tightly together with the help of adhesive. In this process the wooden planks are kept in the machine glued together and with help hydraulics or pneumatic system pressure is created to join the planks. The machine is geared towards improved production.

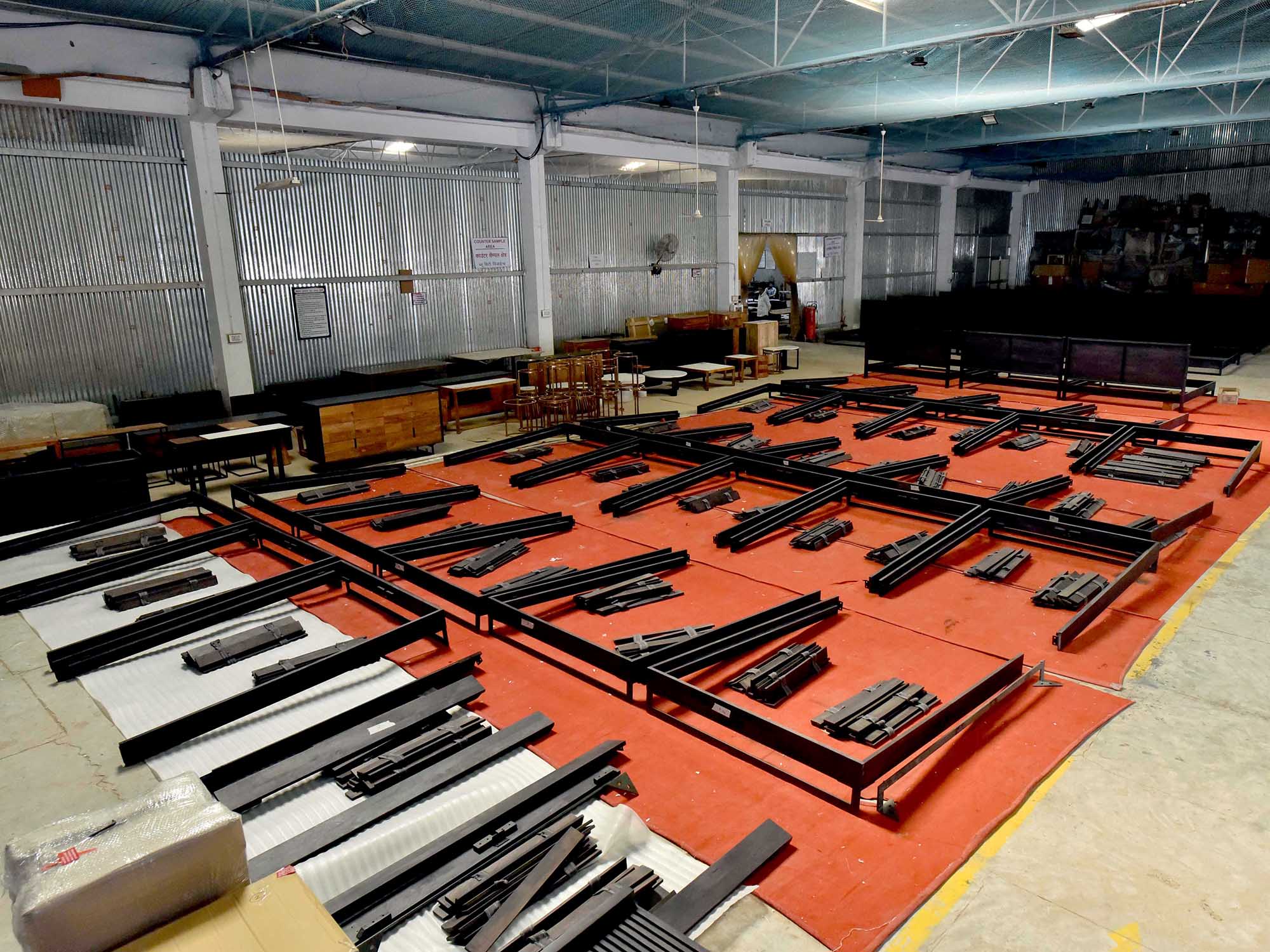

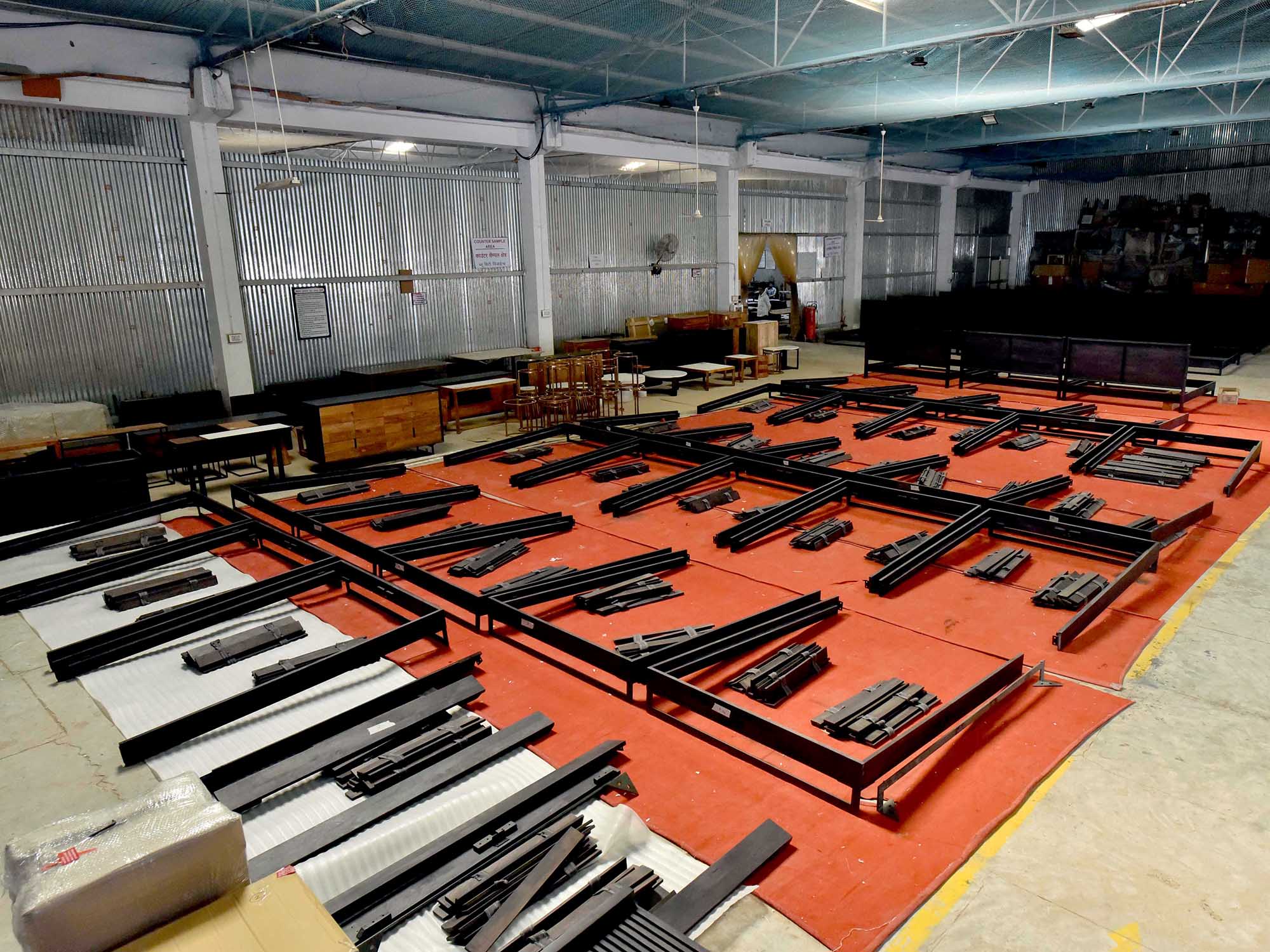

Semi-finished product is allotted to different and specified Assembly Departments according to their product jobs for further needed operations.

Once we are done with clamping carrier, the planks of specified products are clubbed together with a product code and an assembly kit is created with designated job number. Further, an in-line personale is appointed who puts the material on test to inspect if there are any external factors that could harm the life of the woodworking. When and only if the material cracks the test, it is eligible to go for further process in the making which includes;

Once the woodworking has gone through the in-line inspection, the clubbed planks are than finished through the wide belt sander which allows to achieve cleaner, softer and smoother surface and are ready to be used for assembly. They are capable of offering substantial output every time. Further step in the process would be putting the semi-complete product through a Panel Saw. This is used to cut a large panel or plank into accurate desired size. Panel saw makes it possible to get the same dimensions repeatedly and resulting into wastage at its minimum.

Now, that the planks have gone through production and machine process and been constructed into a semi-finished product of appropriate dimensions, it is allotted to different and specified Assembly Departments according to their product jobs for further needed operations.

Once the product is produced, they have to go through internal quality audit team who make sure that the product compromises nowhere, be it in quality or presence. Our firm follows the ‘Zero Tolerance’ policy. So, if or when any issue occurs it is sent back to the production team for rectification. Only 100% approved assembled products are sent for finishing stage.

Semi-finished product is allotted to different and specified Assembly Departments according to their product jobs for further needed operations.

Once we are done with clamping carrier, the planks of specified products are clubbed together with a product code and an assembly kit is created with designated job number. Further, an in-line personale is appointed who puts the material on test to inspect if there are any external factors that could harm the life of the woodworking. When and only if the material cracks the test, it is eligible to go for further process in the making which includes;

Once the woodworking has gone through the in-line inspection, the clubbed planks are than finished through the wide belt sander which allows to achieve cleaner, softer and smoother surface and are ready to be used for assembly. They are capable of offering substantial output every time. Further step in the process would be putting the semi-complete product through a Panel Saw. This is used to cut a large panel or plank into accurate desired size. Panel saw makes it possible to get the same dimensions repeatedly and resulting into wastage at its minimum.

Now, that the planks have gone through production and machine process and been constructed into a semi-finished product of appropriate dimensions, it is allotted to different and specified Assembly Departments according to their product jobs for further needed operations.

Once the product is produced, they have to go through internal quality audit team who make sure that the product compromises nowhere, be it in quality or presence. Our firm follows the ‘Zero Tolerance’ policy. So, if or when any issue occurs it is sent back to the production team for rectification. Only 100% approved assembled products are sent for finishing stage.

The final and the last phase in the cycle would be the finishing stage. The foremost purpose of introducing the product to this stage would be providing a protection and adding some more artistic value to it.

This stage is mainly compromises of three steps.

It is the primitive stage of finishing process. For sanding power tools like wide belt sanding machine are used. For elements that needed to be finished manually we use pneumatic hand sanders. The concern you put into this process will determine the quality of finish. Therefore, we appoint highly trained craftsman for the purpose.

This phase is followed by sanding where we finish our product with dust free finishing material like stain, sealer, lacquer, wax, shellac, etc. The scheme behind polishing is not only to give the material an extra glossy finish but to layer it with something that provides a protection to resist moisture and scratches. It is a time-consuming process that needs practice before achieving the best result. Thus, to deliver the best polished version of the woodworking we handover this task to our qualified workers only, who put all their efforts to come up with a shine that would light up your home.

This final stage is for the benefit of our importers. To avoid any defects our expertise of Internal QC Personnel checks various aspects of the furniture such as, performance check, stability check, size measurement, material and colour check etc. If any glitch is founded, a same inspection report is sent for rectification before presenting it to the External QC Personnel.

The final and the last phase in the cycle would be the finishing stage. The foremost purpose of introducing the product to this stage would be providing a protection and adding some more artistic value to it.

This stage is mainly compromises of three steps.

It is the primitive stage of finishing process. For sanding power tools like wide belt sanding machine are used. For elements that needed to be finished manually we use pneumatic hand sanders. The concern you put into this process will determine the quality of finish. Therefore, we appoint highly trained craftsman for the purpose.

This phase is followed by sanding where we finish our product with dust free finishing material like stain, sealer, lacquer, wax, shellac, etc. The scheme behind polishing is not only to give the material an extra glossy finish but to layer it with something that provides a protection to resist moisture and scratches. It is a time-consuming process that needs practice before achieving the best result. Thus, to deliver the best polished version of the woodworking we handover this task to our qualified workers only, who put all their efforts to come up with a shine that would light up your home.

This final stage is for the benefit of our importers. To avoid any defects our expertise of Internal QC Personnel checks various aspects of the furniture such as, performance check, stability check, size measurement, material and colour check etc. If any glitch is founded, a same inspection report is sent for rectification before presenting it to the External QC Personnel.

The customer who walks into our premise would step out with a bag full of satisfaction and of course many elegant home furniture.

The interaction between us and our buyers is a critical factor that ensures their satisfaction. For this purpose we are occupied with a team who has the knack of being patient enough and are supremely skilled to understand what a customer tries to convey. As a B2B supplier, we try to drive out the basic thought or image of the product a customer has in its mind by making utmost use of the interaction to ultimately deliver them exactly what they want.

As a B2B supplier, we try to drive out the basic thought or image of the product a customer has in its mind by making utmost use of the interaction to ultimately deliver them exactly what they want.

All Rights Reserved © 2023 Blue City Designs